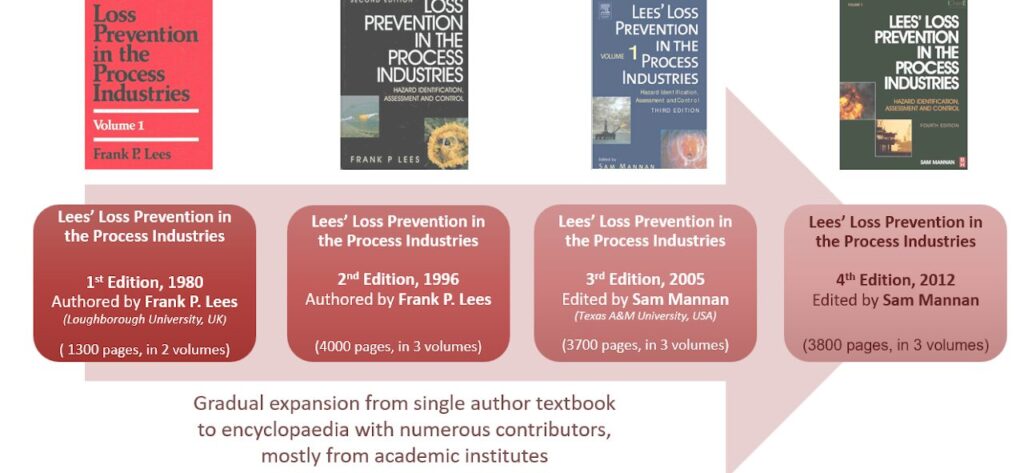

Announcing the 5th Edition of this invaluable resource

Recognized as the standard work for chemical and process engineering safety professionals and trusted for 30 years, it provides the most complete collection of information on the theory, practice, design elements, equipment, regulations and laws covering the field of process safety. An entire library of alternative books (and cross-referencing systems) would be needed to replace or improve upon it, but everything of importance to safety professionals, engineers and managers can be found in this all-encompassing three volume reference instead. The 5th edition is not just an update of previous editions but a complete reorganization and re-write to include all the known practices and fundamentals of process safety plus developing areas driven by technological advances and industry’s look to the future. It will have more breadth and depth than previous editions while being more concise.

The book will also be published in a digital format to make it fully searchable. Besides a wealth of references, it will have internal hyperlinks that interconnect relevant chapters.

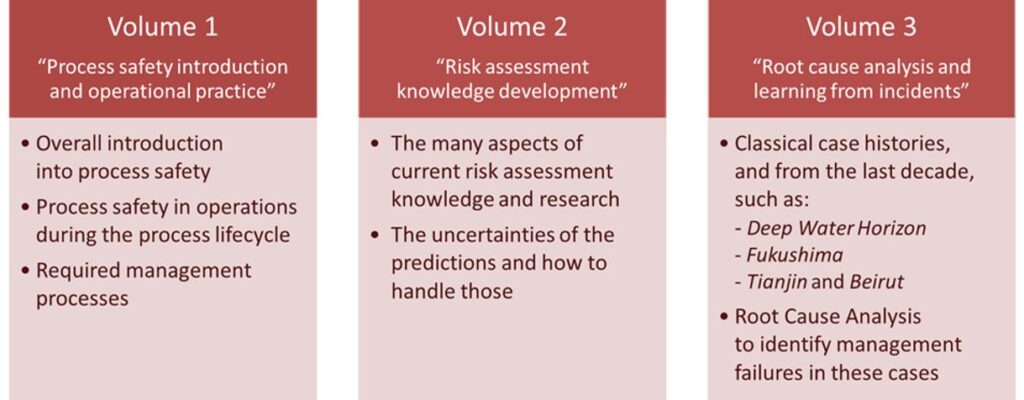

Volumes of Lees 5th Edition

The planned three volumes in Lees’ edition 5 will provide an overview of current process safety knowledge and relevant methods.

VOLUME 1

Process Safety Practice (Design, Management and Operations)

VOLUME 2

Process Safety Science and Technology (Risk Assessment and Management and Underlying Science)

VOLUME 3

Process Safety Incidents and Their Learnings

- The structural organization of the three volumes into Parts, Chapters, Sub-chapters, and Sections and Sub-sections will make it easier to find content related to a particular topic.

- To get recognition of the work, all authors and reviewers of a contribution put their name and affiliation below the title of the contribution as in a journal paper. Editors will be named at the opening page of the part they are responsible for.

Vision for Lees’ Handbook

- To be the ‘Go To’ reference-quality handbook for managers, technical personnel with process safety responsibilities, and students and academia involved in preventing losses.

- Strive to define what must be done at each stage in the ‘Life Cycle’, how this can be accomplished, and how these activities can be effectively managed.

- Provide sufficient history, background, and evolution trends to make the content meaningful. Lees 5 shall show relationships among the various loss prevention aspects.

- Provide sufficient external and internal references to document the methods and provide further guidance to those seeking more detailed understanding.

- Make the content relevant to practitioners around the world in both industry as well as academia.

- Comprehensively keep pace with technological developments in the process safety field with an electronic edition.